|

|

INFORMATION AREA

Special Feature

|

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

End Up To Top (ET)

Description: The end of the yarn tied up on the top of the cone.

|

|

|

| |

|

|

|

|

| |

|

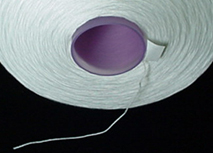

Tie End Up (TI)

Description: The end of the yarn tied on the middle of the cone.

|

|

|

| |

|

|

|

|

| |

|

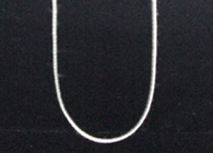

Trail End (TE)

Description: Leave the length of the end of the yarn about 30 cm.

|

|

|

| |

|

|

|

|

| |

|

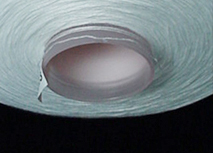

Rounded Edges (RE)

Description: Make the edges of the package soft by using our pressure machine which the shape of yarn look similar like �Pine apple� after pressed. The purpose is to help in dyeing process.

|

|

|

| |

|

|

|

|

| |

|

Heat Set (Steaming)

Description: Using the hot steaming machine in order to fixed the yarn torsion. Our machine were controlled the temperature at 130 Celsius for Spun and 120 Celsius for Core Spun.

|

|

|

| |

|

|

|

|

| |

|

Oiling (Lubrication)

Description: The features of the yarns for subsequent processing by using lubrication the co-efficient of friction of the yarns are Reduces; this eliminates abrasion, dust and fly.

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

| |